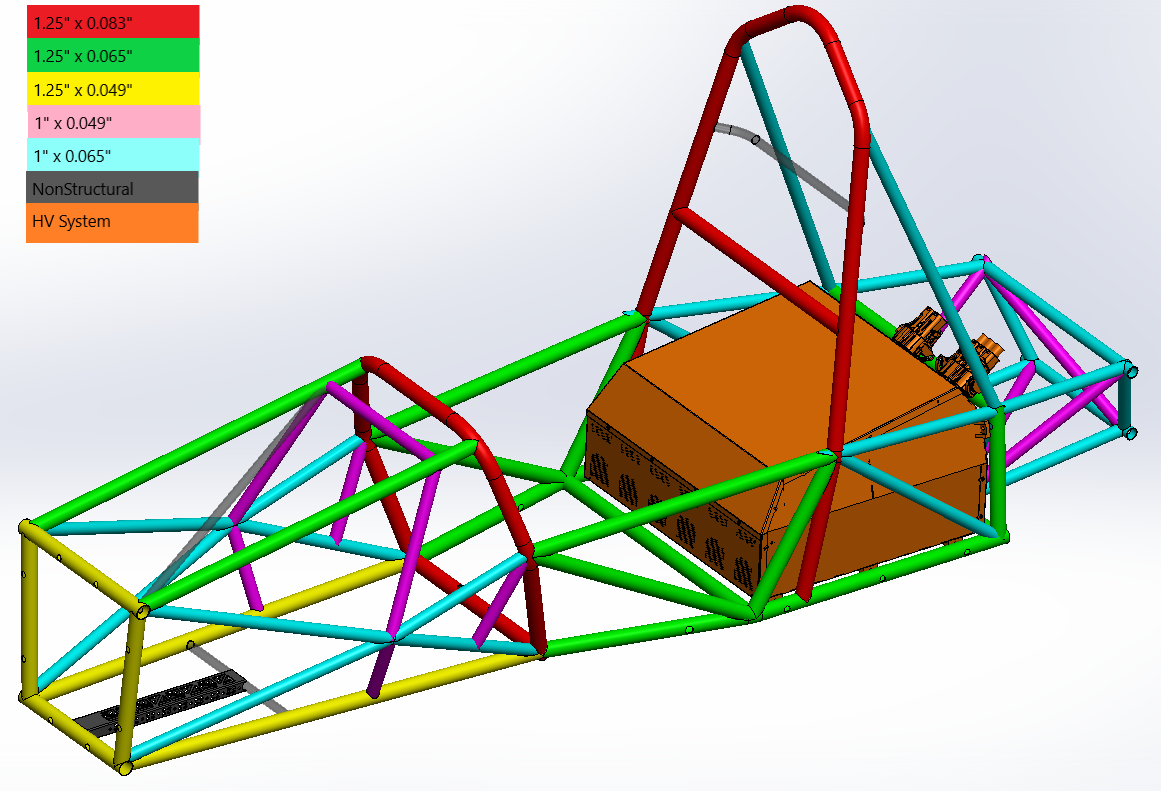

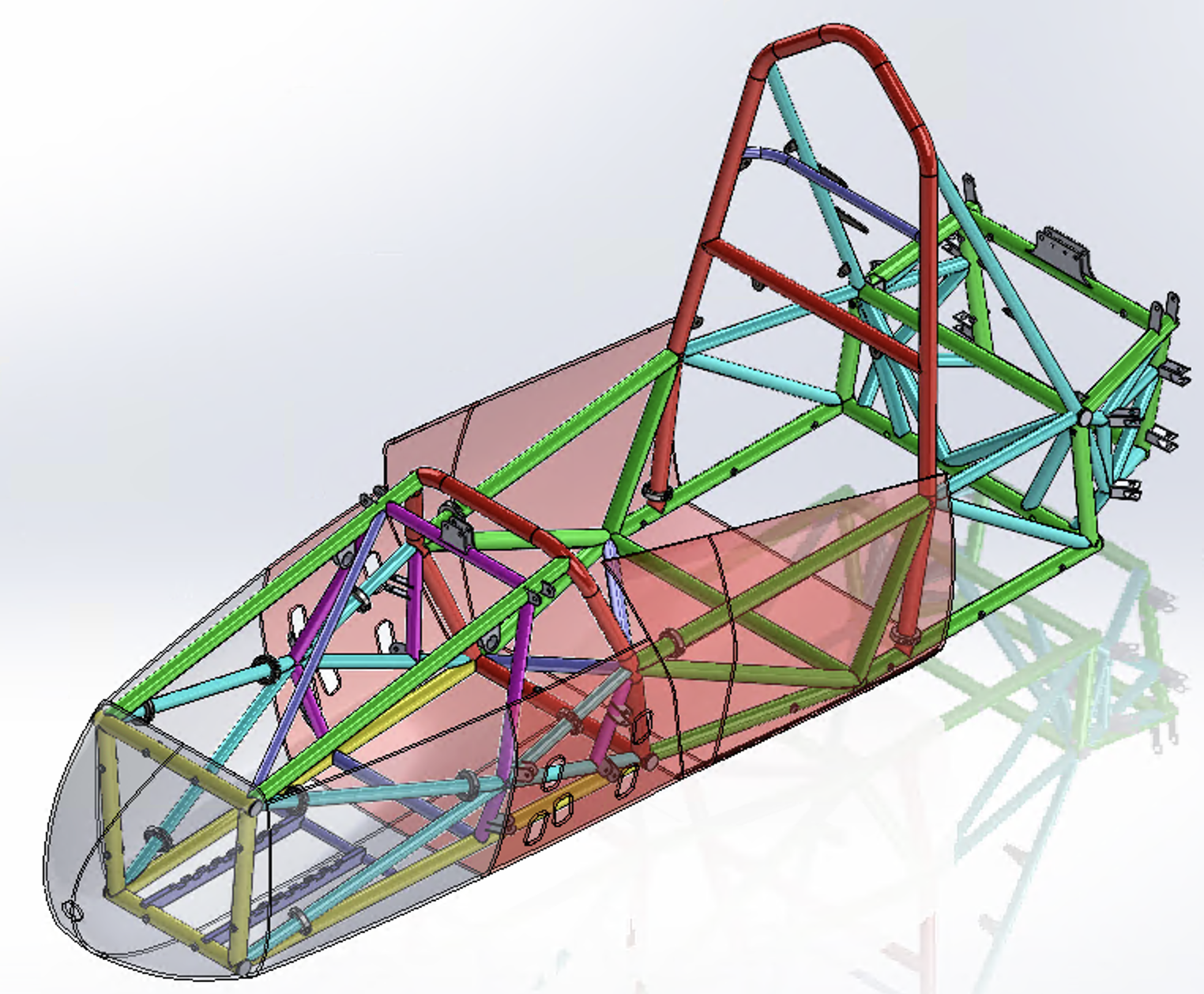

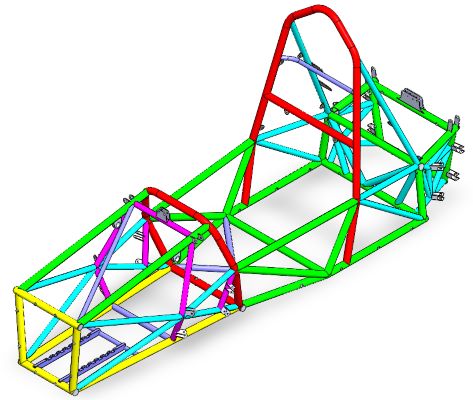

Full CAD Model

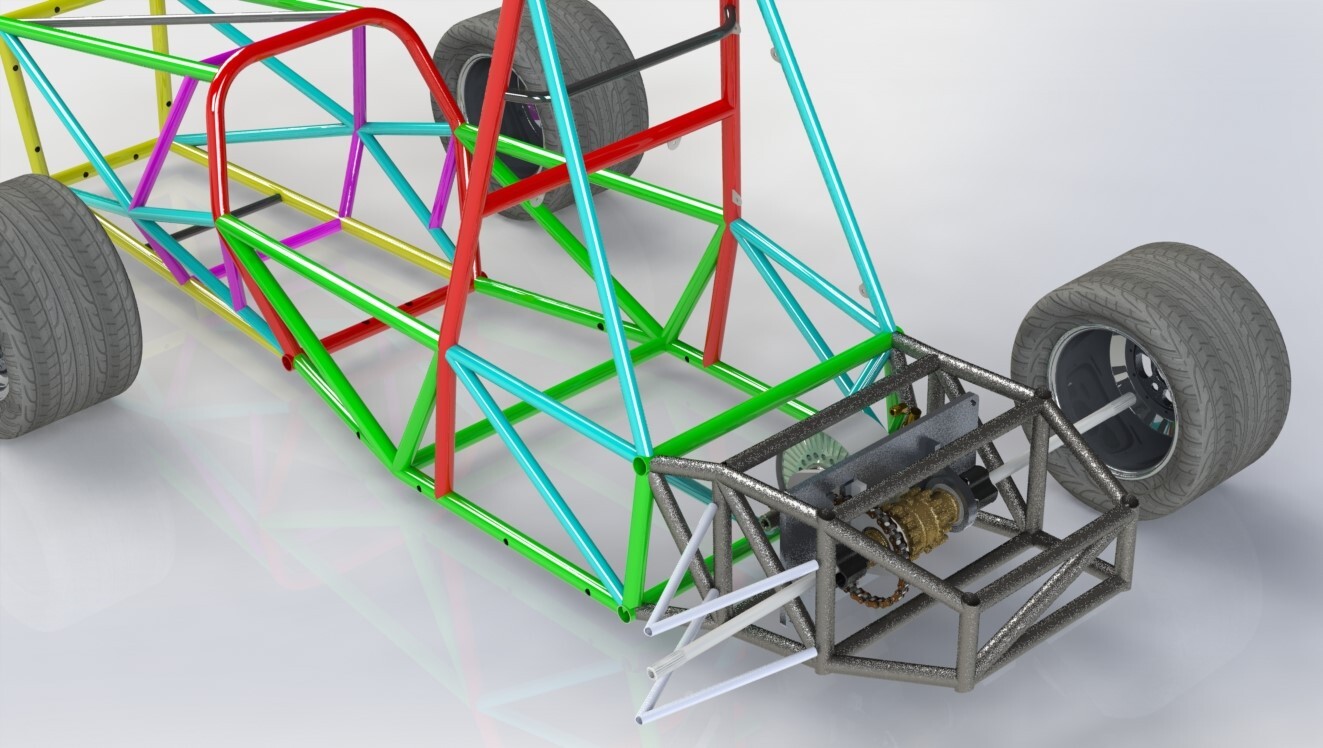

In this project, I was given the unique challenge of only redesigning the rear half of an IC chassis to become an EV chassis. The fore part of the EV chassis has the same suspension pick up points, pedal box rail, and steering column as its previous IC chassis.