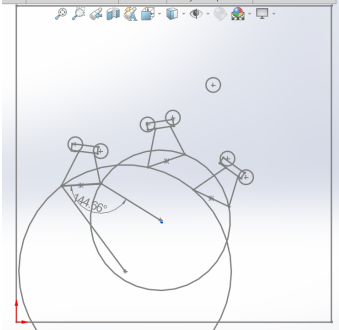

2D Layout of Board

The first step of this project was to create a sketch of the playing field for the board and location of the buttons. The next step was to draw inital designs for a ground pivot point and linkage lengths.

Create a 4 bar linkage that can press the most arcade buttons that appear on a board in under 1 minute.

The first step of this project was to create a sketch of the playing field for the board and location of the buttons. The next step was to draw inital designs for a ground pivot point and linkage lengths.

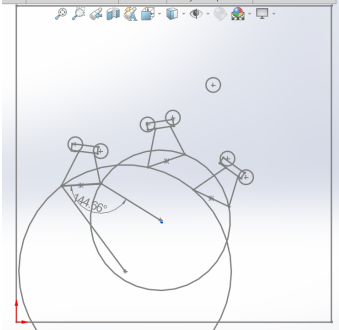

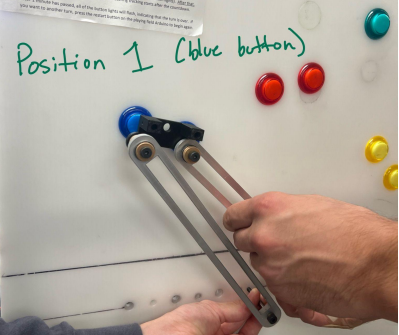

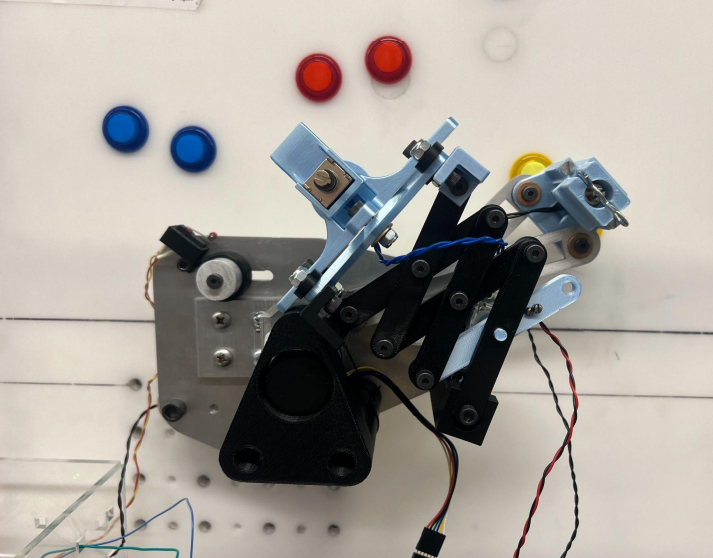

This photo shows the first iteration of our coupler, the part of the machine that hits the buttons on the playing field.

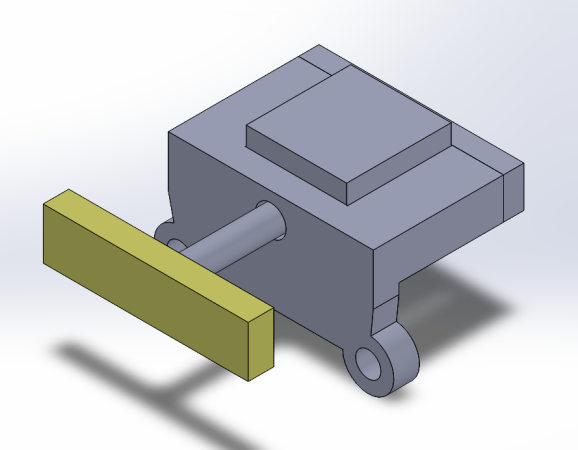

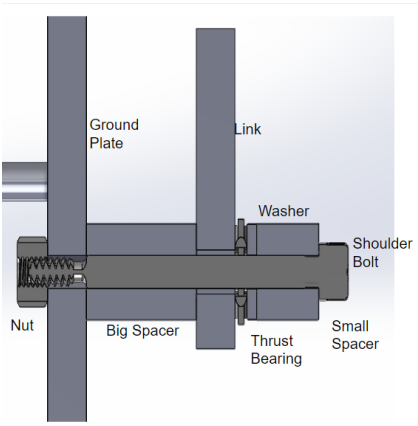

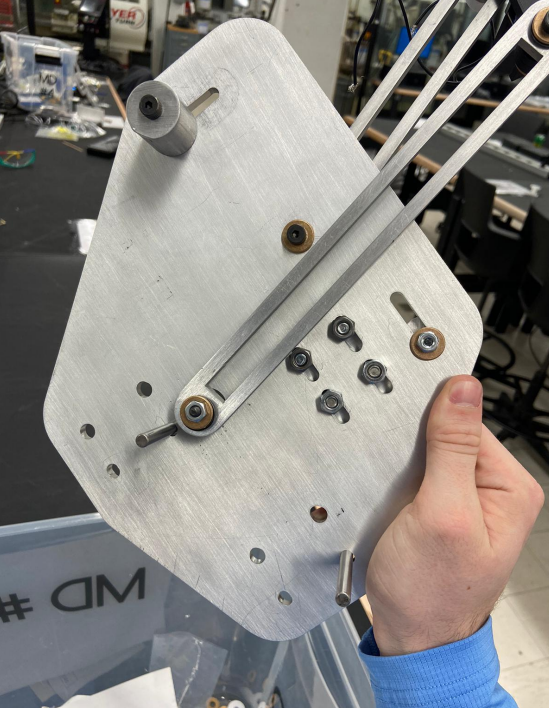

Here we have the linkage assembly for one of our links. We are missing an extra thrust bearing that will make the system frictionless so it can move without a problem, this was the first iteration of the system.

This was the first bit of manufacturing we did for the project. We 3D printed the coupler, waterjet the links, and pressfit the bearings in the links.

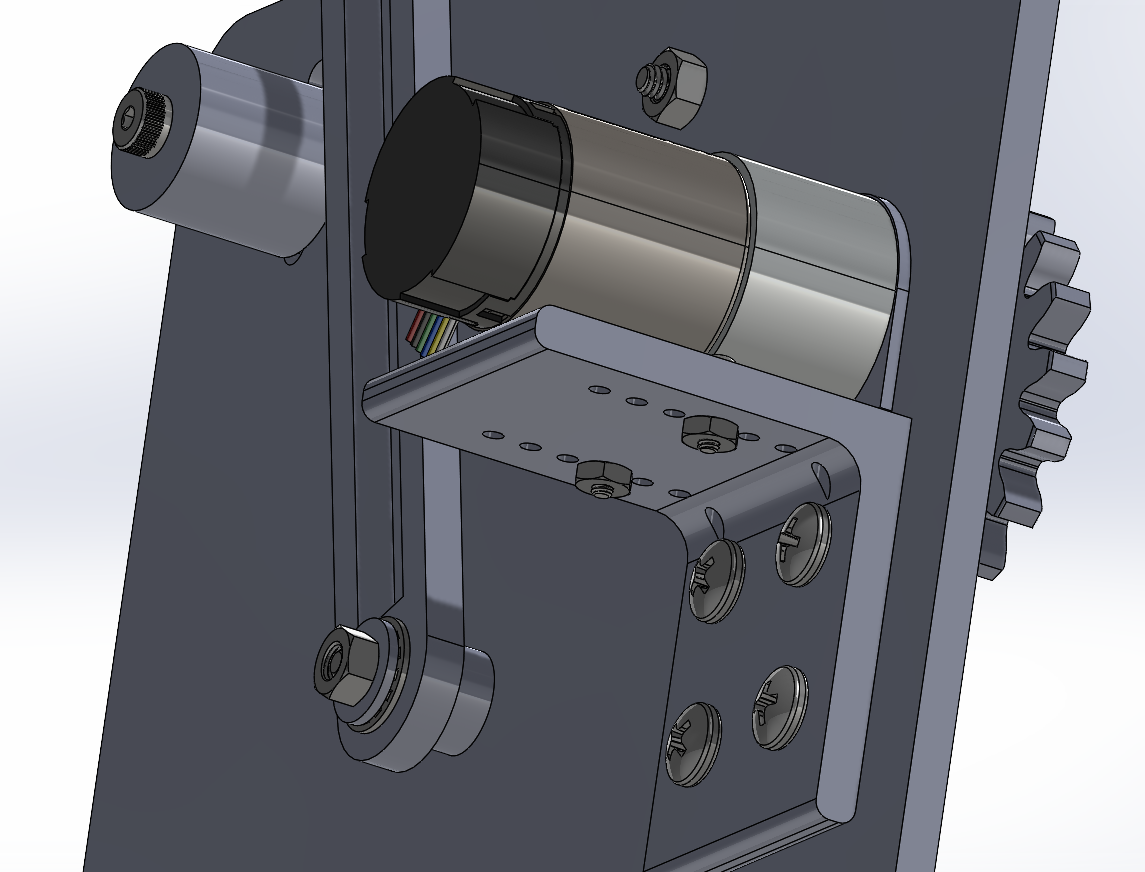

This CAD includes gears, a pololu 12v dc motor, the links, and all the hardware to mount everything to the board. It holds the DC motor in place with the bracket in the front, and has a transmission ratio of 1.0107.

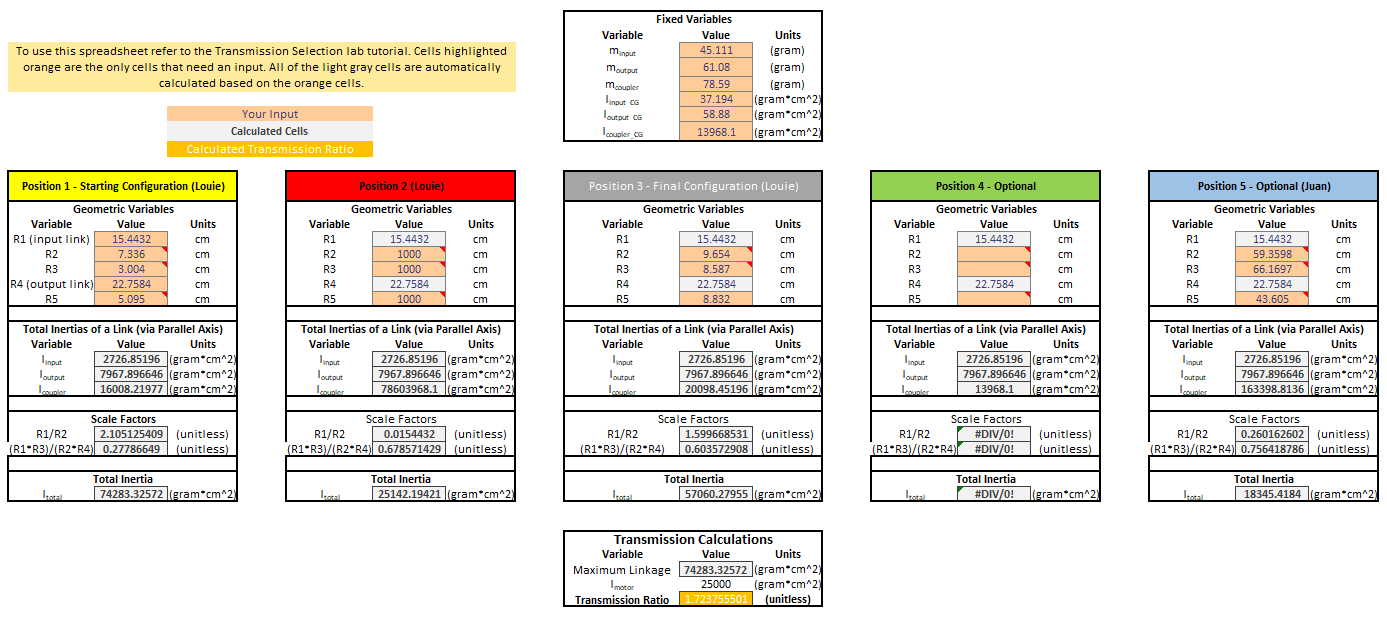

This spreadsheet allowed us to calculate the transmission ratio of the linkage and the moment of inertia of the motor using the parallel axis theorem.

Here we have the ground plate of our assembly, which was waterjet and finished on a mill, the links are made via the same process, and the spacers were made on a lathe.

Here we can see the final Mechanical Assembly of the 4 bar linkage button pressing mechanism. The blue and black PLA in the front is our actuating bonus button presser that goes on start up. You can see various electrical components like a limit switch and solenoids in this photo.

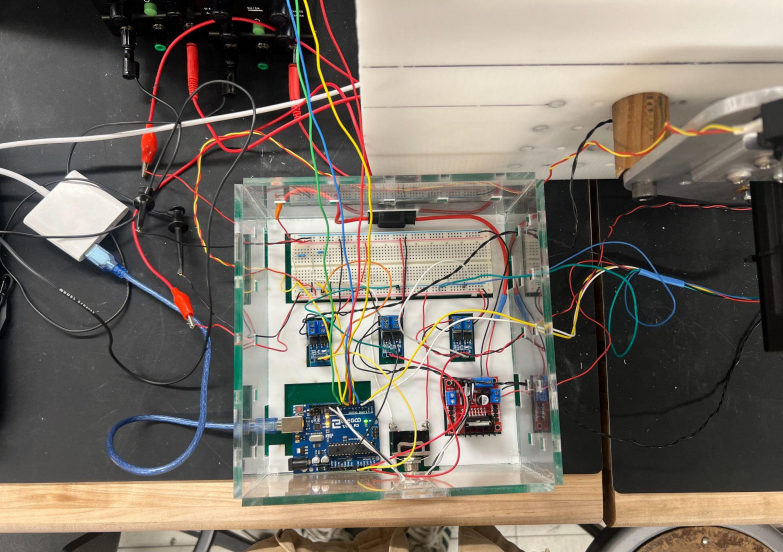

The brains of this project is an Arduino UNO. The DC motor is connected to a dual H-Bridge motor driver that is able to switch the polarity of the motor. Each solenoid, and the servo to actuate the bonus button mechanism are connected to a transistor to be able to move them only when they are over the button.